Friction Stir Welding is a solid state joining

process where the workpiece is joined using a rotating tool. The

interaction between the workpiece and the tool generates heat due to

plastic and frictional dissipation.

HBS Engineering can supply industrial partners or research institutions

with know-how within the field of both manufacturing and design of

friction stir welded components.

Pilot project or R&D projects can be carried out in our workshop or

together at the clients facilities.

COPYRIGHT by HBS ENGINEERING

Friction Stir Welding

Friction stir welded plates in 7075 T6.

Friction stir sport weld af overlap steel plates.

Friction stir welding machine based on a modified milling machine.

Friction stir welding setup of 7075T6 plate.

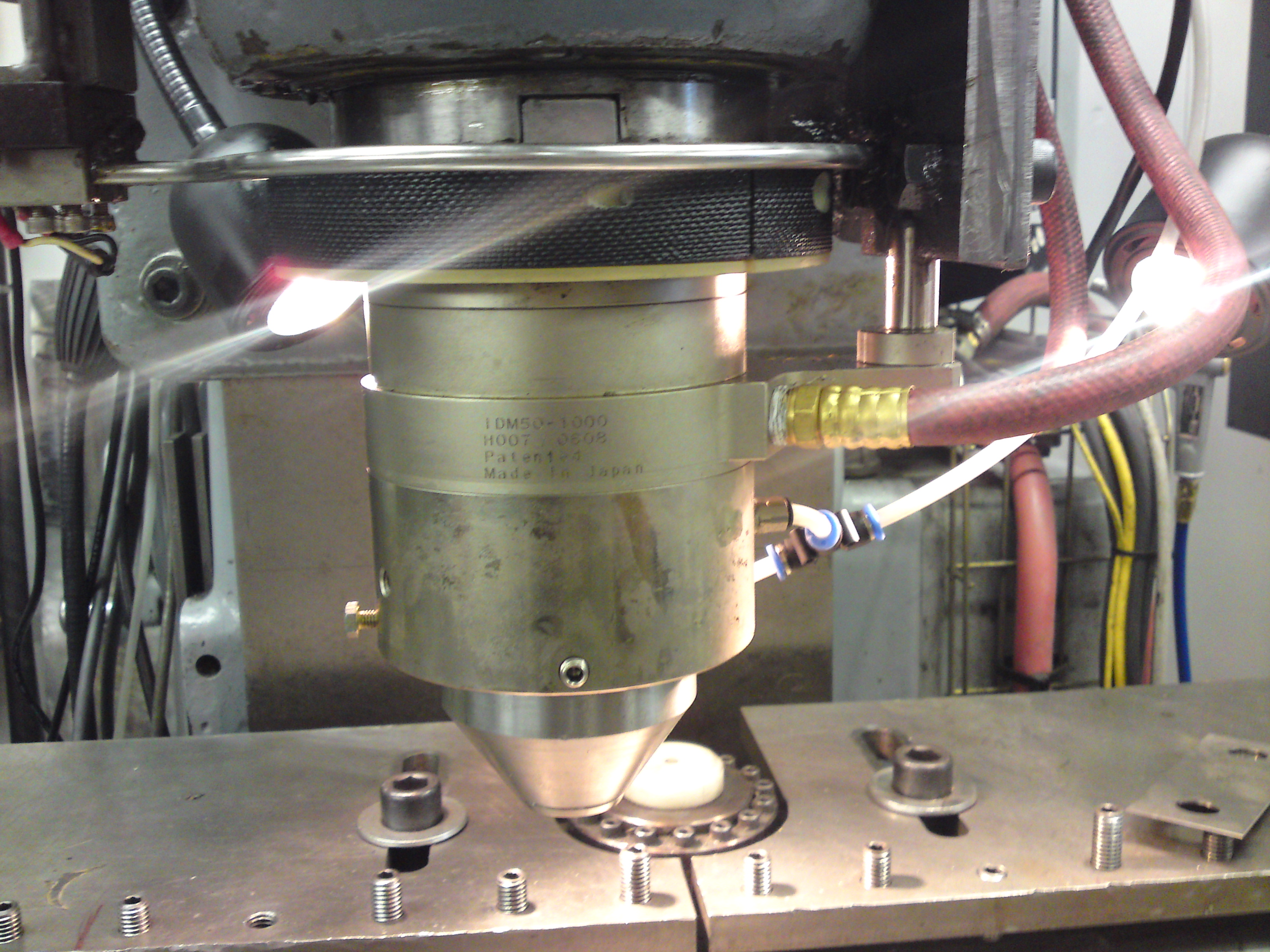

Friction stir spot welding of steel plate

Friction stir spot welding tool in PCBN (Poly Crystaline Boron Nitride) by Mega Stir Technologies.

Friction stir welding machine at Mega Stir Technologies, Utah, US.