We have during the last five years made project

within R&D, Design for Manufacturing and strenght analysis.

Some references are given below:

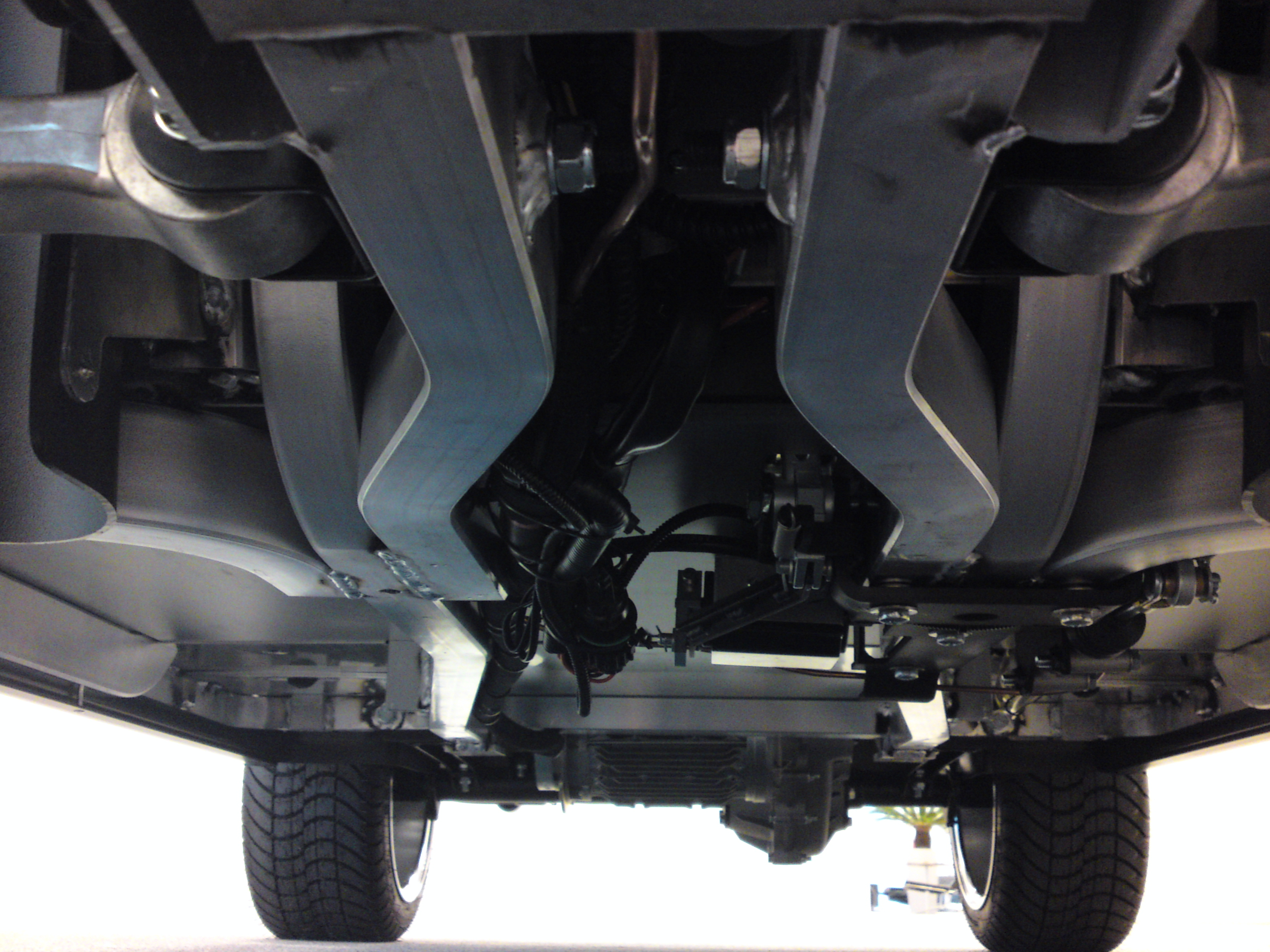

Garia, Golf car

Garia is a Danish manufacturer of electric golf cars. HBS Engineering

have taken part in the product development since April 2006. We have

been responsible for the strenght analysis and welding specification

for the chassis components.

References

Kleemann, Sportscar

.. is the world famous tuner of Mercedes Sportscar placed in Farum, Denmark.

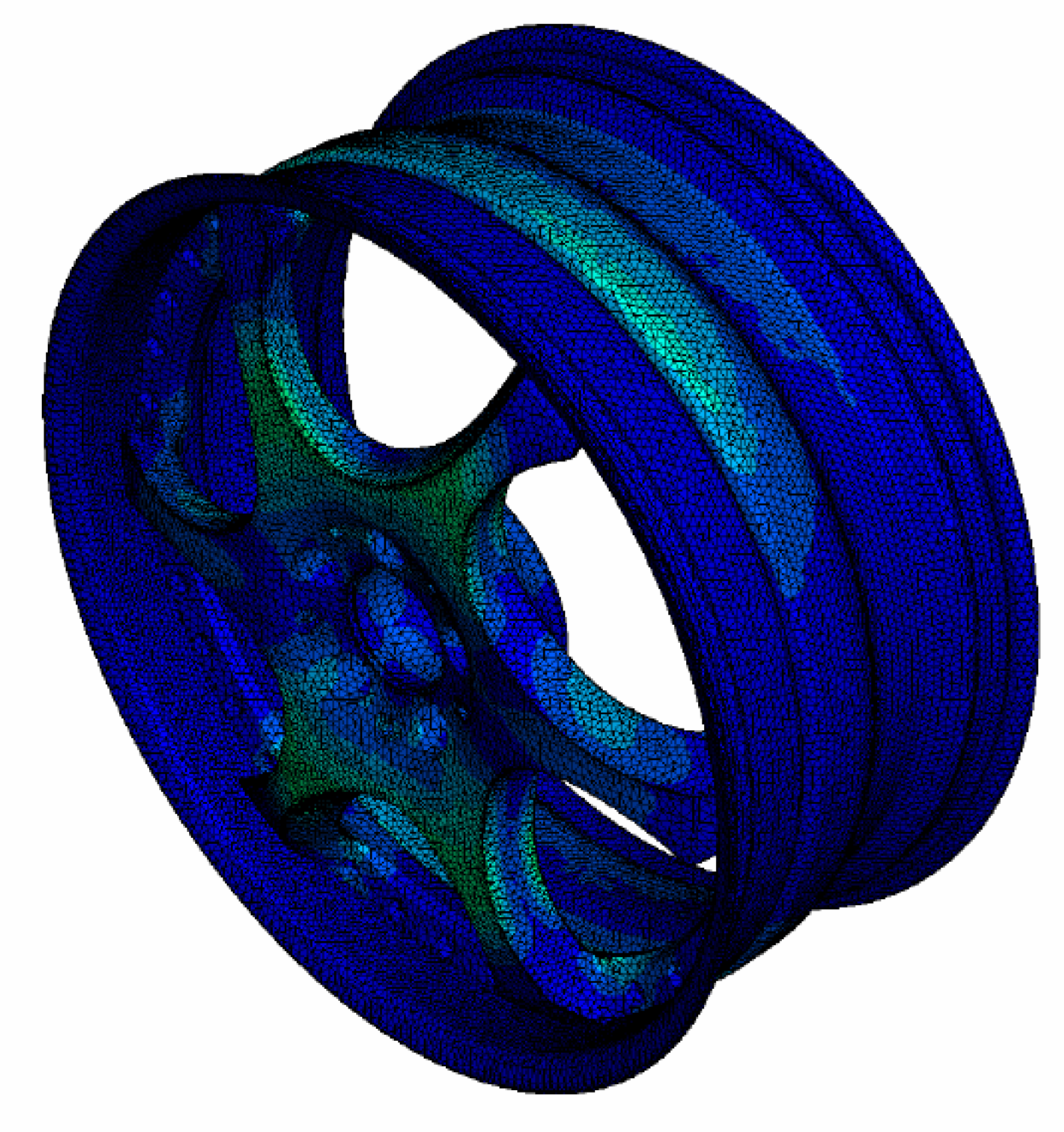

We have supported Kleemann with development of a new supercharger and intercooler system based on optimization using Comsol and Matlab - combined with our experiense in combustion engine optimization. Verification of the strengh criteria for TUV approval of wheels using FEM has been performed and proposal for design changes/optimization. Furthermore, we have assisted with type approval documentation.

.. is the world famous tuner of Mercedes Sportscar placed in Farum, Denmark.

We have supported Kleemann with development of a new supercharger and intercooler system based on optimization using Comsol and Matlab - combined with our experiense in combustion engine optimization. Verification of the strengh criteria for TUV approval of wheels using FEM has been performed and proposal for design changes/optimization. Furthermore, we have assisted with type approval documentation.

Stress field in the new Kleeemann TS6 3-piece Aluminium Wheel

Exxon Mobil

Exxon Mobil is one of the worlds leading manufacture of steel pipes. Friction Stir Welding is an alternative manufacturing process to the GMAW proces currently used. Numerical models for simulating the thermomechancical conditions in the pipes have been developed.

Alfa Laval

Alfa Laval manufacture heat exchangers joined by laser welding. A thorough investigation of a subsection of such components have been analyzed in collaboration with DTU using Abaqus.

Zenvo

The Danish Super car. During the initial stage of the development, the areodynamic of the car profile were examined.

The Danish Super car. During the initial stage of the development, the areodynamic of the car profile were examined.